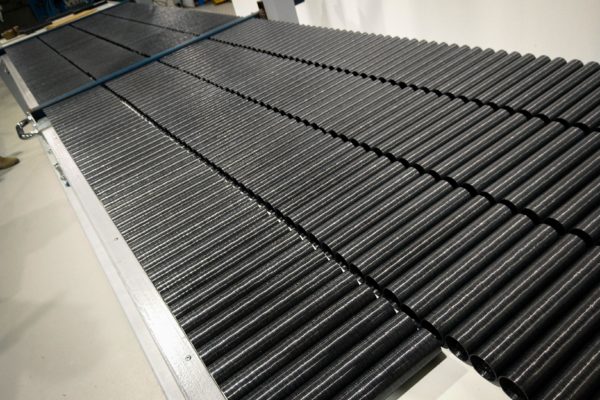

We’ve recently added a new winding machine to our volume manufacturing facility, which will be in operation soon to add extra capacity coming into Christmas. Adding additional machinery gives us the flexibility to take on more low volume custom work for high performance applications without interrupting existing production.

CST is proud to see AMSL Aero’s Vertiia eVTOL aircraft making headlines in the Australian Financial Review.

CST’s engineering and materials knowledge have been supporting the wing spar development that will see this electric Vertical Take Off and Landing aircraft flying in 2021. Congratulations to the team at AMSL Aero and all involved for a job well done.

Share this with your friends

Saving the world one tube at a time…

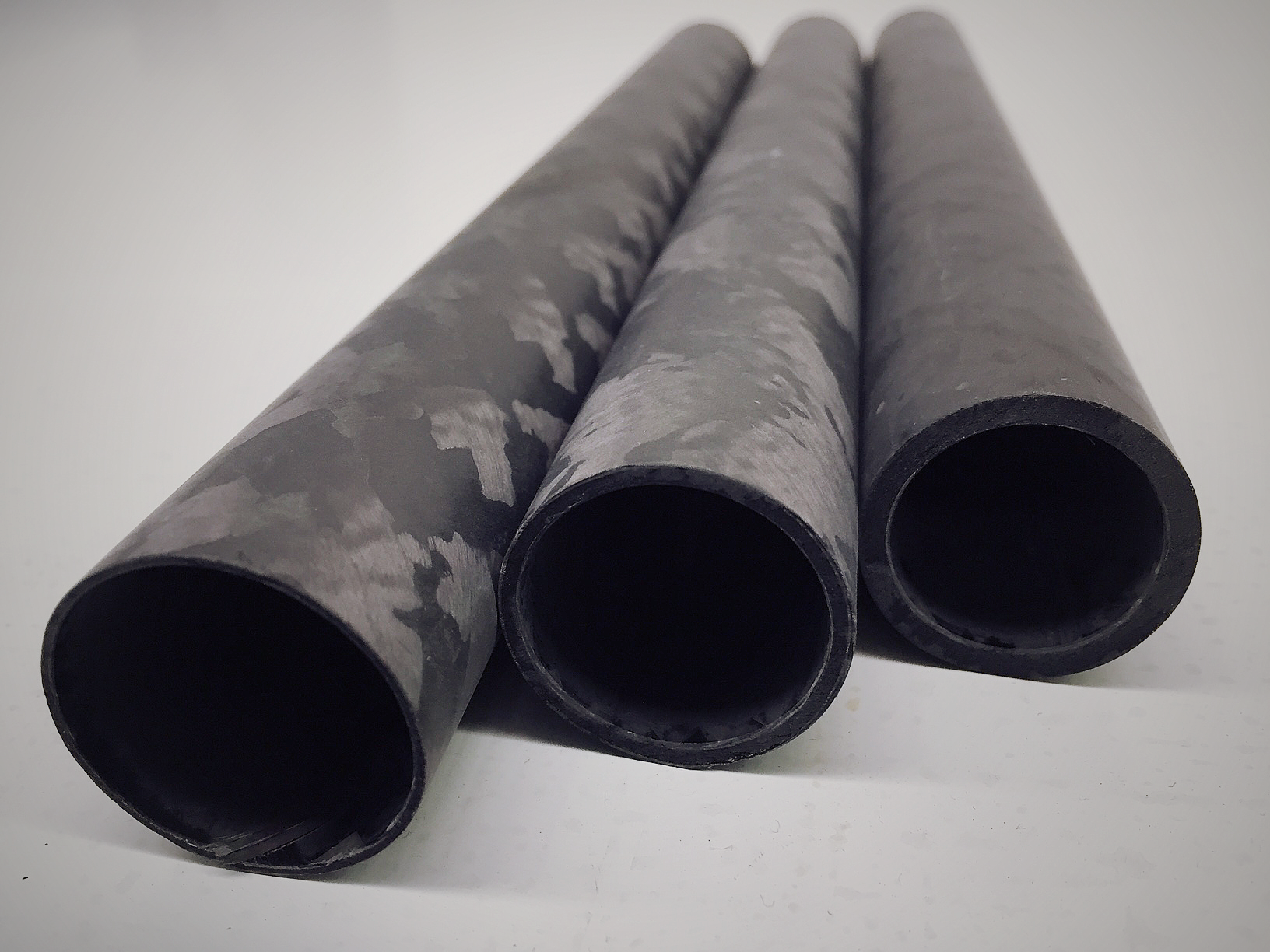

Final QC for impact energy absorption tubes on their way to North America today.

When we make sailing masts and structural tubes, we attempt to make a strong, durable product that will stand up to a regular beating and won’t delaminate.

Our energy-absorbing products are quite the opposite! We design them to delaminate and create a maximum surface area at a threshold load to absorb the energy of an impact.

Nice to think our composites could save someone’s life.

Share this with your friends

Another awesome CNC machine being delivered to our new Sydney facility, strengthening our existing in-house capabilities for tooling development, metal parts and mouldings, with the ability to work within 6 micron accuracy.

This particular machine has a special history, first owned by the late, great Dr Victor Chang, Australia’s gifted heart surgeon, for his company’s (Heartware) for the manufacture of artificial heart components in Australia.

Share this with your friends

Another order for precision ground tubes about to take off for the US today, utilizing our precision centreless grinding technology.

For over a year now our skilled technicians have been machining outer surfaces diameters on our composite tubing to standard tolerances of within +/- 50 Microns.

It’s exciting times at CST Composites as we introduce a range of new equipment, machining and finishing capabilities.

“Fast is fine, but accuracy is everything” – Wyatt Earp.

Get in contact with us today to get your hands on one of our precision products.

Share this with your friends

In 2017 and earlier this year, CST has been a sponsor for the team at Technico Solar Boat (TSB) and provided them with composite carbon fibre tubes to be fitted into their solar boats.

TSB is a university project consisting of engineering students from Instituto Superior Técnico that work together on the development of a racing vessel exclusively powered by the sun. TSB participates in worldwide university competitions organised by solar 1.

Here at CST, we saw what TBS was trying to achieve and wanted to support them and their cause. The competition such as the Solar 1 Monte Carlo Cup in Monaco (which TBS competed in, in 2017) are put together to raise awareness and encourage technological innovation in solar energy. Meeting the energy needs in both leisure boats and the shipping industry in an environmentally and sustainable fashion.

We are a big believer in environmental and sustainable energy at CST and it was a no-brainer to support TBS in the 2019 Solar 1 Monte Carlo Cup and to support a team of brilliantly clever engineers that are paving the way for the future.

Check out Técnico Solar Boat website to find out more and give them all the support!

Check out these awesome photos of the solar boat in action

(All images provided by our friends at Técnico Solar Boat)

Share this with your friends!

Make sure to check out our website and YouTube channel to stay up to date on all CST activities and events.

NEW Finishing Capabilities - Centreless Grinding

The team at CST Composites is excited to offer a new finishing capability for our composite tubing products. Using precision centreless grinding technology, our skilled technicians now have the ability to produce outer surface diameters on our composite tubing within tolerances of +/- 50 Microns… that’s 0.05 of a millimetre! Even the ants would be happy with that!

We’ve already had success with this innovation, having been put to the test by one of Australia’s leading Supercar Championship teams to supply various sizes of precision ground tubes for a new Supercar featuring in the 2019 Championship.

Centreless grinding of our products is available NOW to all CST customers.

Get in contact with us today to discover how our precision products can take your business or hobby to the next level.

Check out these close up shots of the different surface finishes

Share this post with your friends!

CST Composites ISO 9001;2015 Recertification

We are proud to announce that we have achieved recertification for both manufacturing facilities under the new ISO9001;2015 standards.

As a growing business, we guarantee to our customers a professional and transparent operating/organisational system that meets the standard recognised by over 168 nations around the world, through this recertification.

This allows customers past, present and future to have peace of mind that CST will provide a world leading professional product in a cost effective and timely manner for the mining, industrial and marine sector.

Make sure to check our other posts on our website and social media sites to stay up to date on all elevate CST activities and events

Today we are blowing out the cobwebs and looking back to 2010 when we made the most highly loaded tube in CST history. Transitioning the 95,000 kg working loads into the laminate made it an extremely complex tube to engineer as well as manufacture. We had to ensure that the safety factors were sufficient which resulted in the laminate thickness in some areas exceeding 75mm. Many new production processes were developed for this project, ranging from thick laminate curing to incorporating the metal threaded ends during the winding. This was a great milestone in CST history.